Birla Aerocon is India’s leading manufacturer of Autoclaved Aerated Concrete Blocks: an amazingly Innovative and Green Building Material. What makes it superior is its incredible lightweight and insulation properties. About 1/3rd the density of clay brick, can be laid much quicker, saving time and building costs. Being more resilient to damage helps reduce wastage during transportation. These blocks offer effective & practical solutions for the current building regulations and are manufactured using the latest technologies at India’s most advanced AAC facilities located in Chennai, Surat, Jhajjar & Thimmapur. Construction using Birla Aerocon AAC Blocks boosts up the project by ensuring at least 6-7 LEED Green Building Certification Points.

Birla Aerocon AAC Blocks

Key Features

Birla Aerocon Benefits

Why Use Birla Aerocon AAC Blocks?

1. Energy saving and eco-friendly; helps reduce carbon foot print.

- Manufactured from recycled material with zero wastage

- Quicken up construction by up to 30%

2. Dimensionally accurate & easy workability.

- Factory finished with superb surface finish; easily

accepts renders & plasters - Use of standard tools to cut, saw, chisel, drill & shape

3. Unmatched Properties

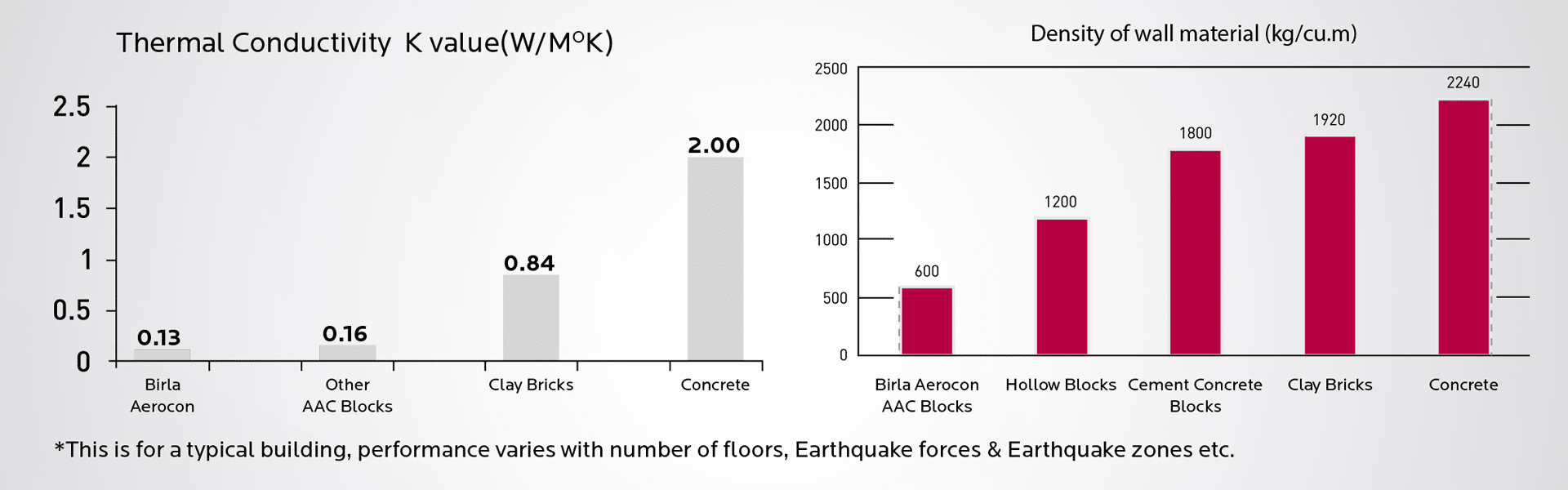

- Super Lightweight; 1/3rd the density of clay bricks

- Non-combustible with superior fire resistance

- Exceptional Thermal & Acoustic Insulation

- No cavity construction; eliminates termites, rodents, pests & fungal growth

4. Guaranteed Savings

- Reduces foundation load of the building up to 30%

- Reduces Power Consumption by 27

- Steel & Cement Savings by 18% & 12% respectively

Birla Aerocon Blocks

A Comparative Analysis

| PARAMETER | AUTOCLAVED AERATED CONCRETE | CELLULAR LIGHT- WEIGHT CONCRETE |

|---|---|---|

| Density (kg/cm) | 551-650 Kg/m3 | x 800-1000 |

| Compressive Strength (N/mm2) | Minimum of 4 | x 1.5-2.5 |

| Dimensional Characteristics | Dimensionally Accurate | x Dimensional Variations |

| Curing | Autoclaving (Steam) | x Normal |

| Pore Size and Distribution | Small and Distributed | x Large |

| Drying Shrinkage | Within IS limits | x No Consistency |

| Curing | Autoclaving (Steam) | x Normal |

| S.No | CRITERIA | UNIT | BIRLA AEROCON BLOCKS | CLAY BRICKS | CONCRETE BLOCKS |

|---|---|---|---|---|---|

| 1. | Face Size | mm | 600 mm x 200 mm | 230 x 75 | 400 x 200 |

| 2. | Thickness | mm | 75- 230 | 115 | 100, 150, 200 |

| 3. | Faster Construction | Yes | Slow | ||

| 4. | Workability | Easy | Moderate | Difficult | |

| 5. | Quality | Highly Consistent – Factory Made | Inconsistent – Manually Made | ||

| 6. | Insulation Properties | Superior | Moderate | Average | |

| 7. | Fire Rating | Superior | Normal | ||

| 8. | Services | Easy | Electric/Plumbing Chasing Difficult | ||

| 9. | Environment Friendly | Green Material | No | ||

| Property | Unit | Value | |||||

|---|---|---|---|---|---|---|---|

| Face Size## | mm | 600 x 200 | |||||

| Thickness* | mm | 75 | 100 | 125 | 150 | 200 | 230 |

| Dry Weight | Kg | 5.25 | 7 | 8.75 | 10.5 | 14 | 16.10 |

| Compressive Strength** (min) | N/mm2 | 3 | |||||

| Normal Dry Density | Kg/m3 | 551-600 | |||||

| Thermal Conductivity | W/m-k | 0.15 | |||||

| Sound Reduction*** | db | 37-42 | |||||

| Fire Resistance-load Bearing (200mm Thickness) | Hrs | 4 | |||||

| Non Load Bearing (100mm thickness) | Hrs | 4# | |||||

The Birla Aerocon Advantages

1. We provide technical support for lightweight walling-based structural design.

2. Advise on the handling, storage and efficient use of these products so as to

minimise wastage, and thereby costs.

3. Advise on the construction of walls:

• Recommended/Correct Practices

• Training of Supervisors and Masons

• Site audit & feedback process on walling work